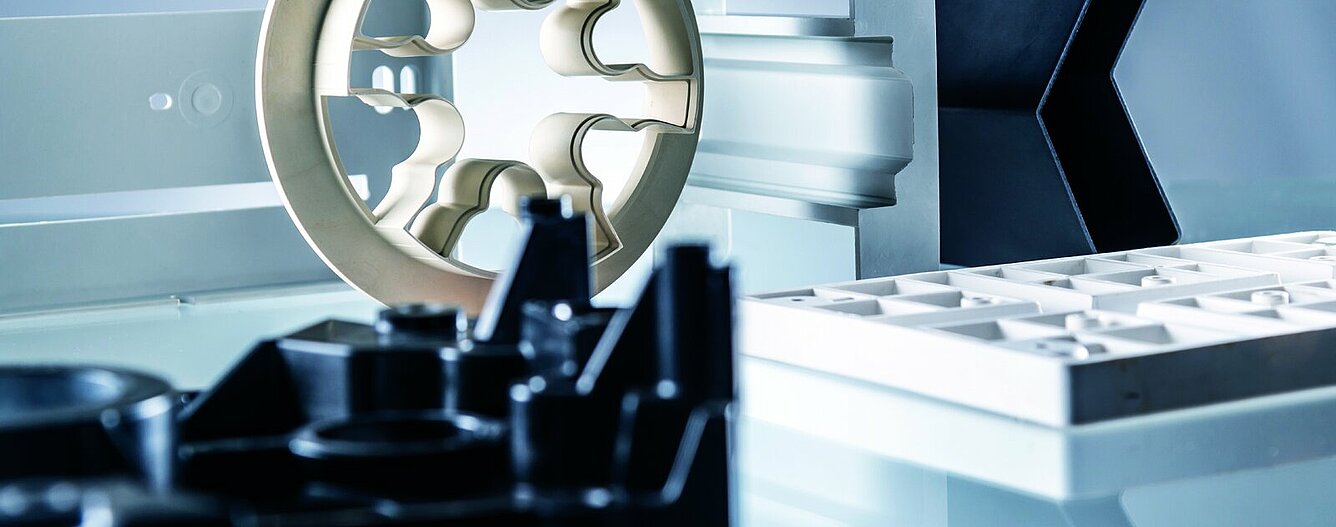

Moulding and injection moulding

Products that are extremely robust: Our speciality at WKT PRESS TEC is the processing of thermosetting plastics – primarily SMCs and BMCs. Using various processes and state-of-the-art machines, we produce components that are used in numerous areas of application.

Process

In injection moulding, we process BMC compounds with fibre lengths of up to 25mm and sprayable SMC with fibres up to 30mm long. The process enables the production of individual moulded parts with the highest-possible surface qualities. Injection-compression moulding is particularly suitable for the production of large components with high surface quality – and cycle times are very short. Both the injection-moulding and injection-compression moulding processes are highly automated, so that they are already viable with medium quantities.

Moulded parts, which are produced from SMC moulding compounds by hot pressing, are preferably used for flat components, but BMC moulding compounds can also be processed. The products are particularly impressive due to their high mechanical strength.

Services

We process BMC, SMC and pourable thermosets. At the same time we support you with thermoset-compatible construction drawings, create a tool concept, and take care of the design and construction of the tools. We're also happy to accept assembly orders and to prepare complete assemblies.